Ultimate Control in Fine Grinding with Advanced Classification

The ROTO-JET jet mill produces a finely ground product and affords you the most advanced and precise control of the particle size distribution. Efficient compressed air usage and total system automation ensure that the highest quality product is manufactured. We bring a wealth of technical and engineering expertise to our manufacturing process and closely involve the customer in every project. The result is a custom engineered and cost-effective grinding circuit operating with the most advanced technology in the size reduction industry.

Enhanced Grinding

The Roto-Jet grinding chamber is a high-efficiency tapered design which maximizes particle collisions and maintains product purity. The grinding chamber features an adjustable bed and variable nozzle configurations to alter bed levels, grinding patterns and gas flow. These unique features provide consistent and efficient grinding.

Adjustable Classifier

The classifier rotor is engineered to provide precise classification of your product. Advanced designs ensure that only specifically sized product is discharged while oversize particles are recycled for additional grinding. The classifier is adjustable within a wide range of speeds to produce the desired particle size.

No Mechanical Heat

As with our other fluid energy jet mills, the Roto-Jet milling machine may be used to grind heat-sensitive products with critical heat limitations. The cooling effect created by the expanding gases offsets the slight heat generated during the grinding and classifying processes.

Automated System Controls

The Roto-Jet System includes the most up-to-date process control technology available. Interlocked sensors and controls work to maintain optimum milling conditions within the system. This advanced instrumentation and control package ensure that the product remains within your exact specifications.

Reliable Construction

The Roto-Jet milling machine is constructed entirely in the USA of only the highest quality components. The low-maintenance design has no moving parts and can be opened quickly and easily for inspection or cleaning. All parts are made in the USA which guarantees rapid delivery of spare items. Comprehensive engineering and durable construction enable our system to operate continuously 24 hours a day, 365 days a year.

Engineering Support and Service

Roto-Jet mill testing is done at our facility in Pennsylvania where detailed process data can be obtained for your application. Fluid Energy engineers and quality service technicians are immediately available to provide technical assistance and to guarantee that the Roto-Jet System performs to your complete satisfaction.

Rental Systems

Most of Fluid Energy’s advanced jet mill systems are available on a rental basis to fulfill your immediate processing requirements.

Custom Processing

Fluid Energy maintains a facility for fine / ultra fine grinding of your material on a contractual basis. Other services include blending, drying and packaging. Our fully equipped QA laboratories are available for moisture, particle size and custom analyses of your products.

Expertly Engineered Particle Milling and Classification

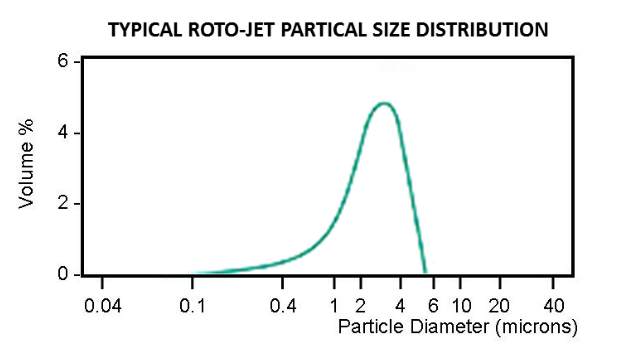

Air or inert gas at elevated pressure is injected through specially designed nozzles directly into the grinding chamber of the Roto-Jet, creating a sonic or supersonic grinding stream. Raw feed is automatically introduced to the Roto-Jet chamber mill by an interlocked feed control system.

The agitation provided by the grinding chamber and nozzle design cause particles to become entrained in the air

or inert gas stream. Particle size reduction is accomplished by high velocity collisions between particles. Small particles are then swept towards the classifier which rotates at high speed above the grinding. The speed of the classifier is preset for the proper sized product and is electronically controlled. Material which is fluidized fine enough to overcome the inertial force generated by the classifier escapes the Roto-Jet mill and is collected as product. Oversized particles are recycled by the classifier back into the grinding chamber for further reduction.

Typical Operating Parameters – Air

| Mill Series # |

Production Capacity(lb/hr) |

Production Capacity(kg/hr) |

SCFM Air @70° F 100 PSIG |

m3/hr Air @21°C F& 6.98 bar |

| 10 |

6 – 100 |

2.5 – 45 |

60 – 100 |

85 – 170 |

| 16 |

400 – 1500 |

18 – 680 |

400 – 800 |

680 – 1360 |

| 30 |

200 – 4000 |

90 – 1815 |

800 – 1600 |

1360 – 2715 |

Roto-Jet Particle Size Reduction Systems Applications

The Roto-Jet is ideal for a wide range of ultra-fine to fine powder grinding and classification applications including:

- Hard to Grind Materials: Lubricants, Polymers, Fibers, Organics

- Heat Sensitive Materials: Waxes, Plastics, Resins

- Coloring Applications: Toners, Pigments, Dyes

- Agricultural Materials: Fungicides, Herbicides, Pesticides

- Abrasive Materials: Minerals, Ores, Polishing Compounds

- Synthetic Materials: Polymers, Plastics, Precipitates